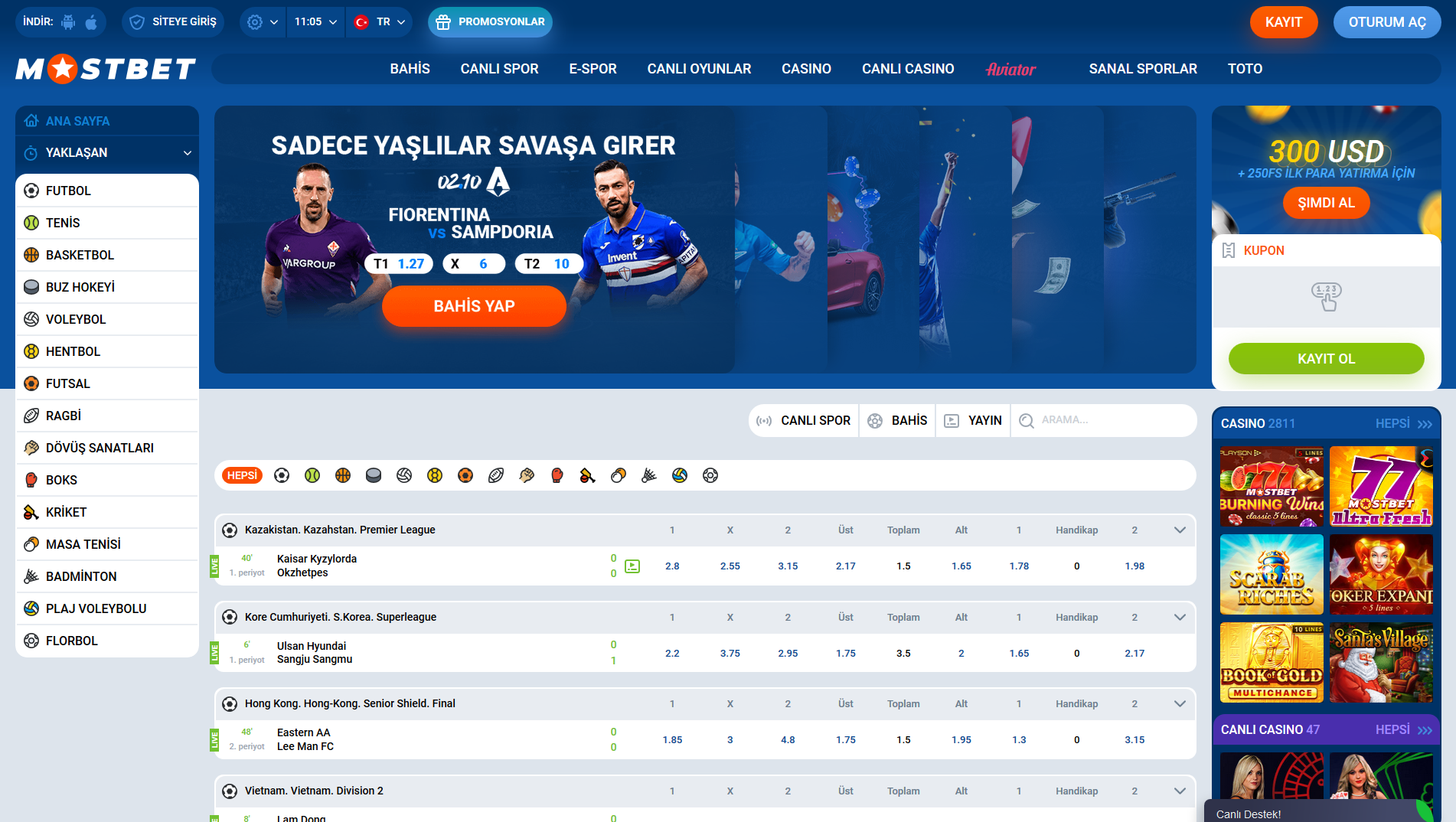

Mostbet giriş

Mostbet giriş parayla mı oynamak istiyorsunuz yoksa spor etkinliklerine mi bahis oynamak istiyorsunuz? Yetkilendirme verilerinizi kullanarak kaydolun ve giriş yapın! Kullanıcılar, Mostbet giriş inde aşağıda tartışılacak olan çeşitli şekillerde çalıştırabilirler.

Mostbet giriş

Henüz kaydolmadıysanız, aşağıda yayınlanan bir hesap oluşturma talimatlarına dikkat edin. Profil sahibi olan kullanıcılar birkaç saniye içinde Mostbet online casino’ya giriş yapabilirler. Yetki vermek için, ana sayfanın üst kısmında bulunan Mostbet Giriş düğmesine tıklamanız gerekir – oyuncunun yalnızca hesaptan veri girmesi ve onu kumar portalında sunulan eğlenceye tam erişimden ayıran son engeli atlaması gerekir.

Mostbet web sitesi, giriş olarak hesap kimliğinizi, cep telefonu numaranızı veya e-posta adresinizi kullanır. Varsayılan olarak, tanımlayıcı veya e-posta belirtilir. Bir telefon numarası kullanarak giriş yapmak için, giriş alanının sağındaki düğmede bulunan simgeye tıklamanız gerekir.

Mostbet’e kayıtlı her oyuncunun hesabına atanmış bir şifresi vardır – kombinasyon hemen aşağıda bulunan alana girilir. Semboller varsayılan olarak gizlidir. Örneğin, şifreyi görmek istiyorsanız, girilen kombinasyonun doğru olduğundan emin olmak için, üzeri çizili gözle düğmeyi tıklamanız yeterlidir.

Yetkilendirme, bahis şirketinin ofisinde ve Mostbet kumarhane portalında www.aztelekom.org/mostbet-az/ aynı anda gerçekleştirilir. Standart kayıt prosedüründen geçmek gerekli değildir – oyunculara giriş yapmak için popüler sosyal ağlardaki hesapları kullanma fırsatı verilir:

- • Telgraf;

- • Ya.ru;

- • Sınıf arkadaşları;

- • Mail.ru;

- • Vkontakte – sayfadan kullanıcı adınızı ve şifrenizi girin ve birkaç saniye süren Mostbet oturum açma prosedürünün tamamlanmasını bekleyin.

Hatırla özelliği, oyuncuları her giriş yaptıklarında bir şifre girmek zorunda kalmaktan kurtarır. Herhangi bir nedenle kaybettiyseniz, uygun düğmeyi tıklayarak da geri yükleyebilirsiniz.

Mostbet’te kayıt

Siteye giriş sadece kayıtlı kullanıcılar tarafından kullanılabilir. Ana sayfaya gidin ve Kayıt düğmesine tıklayın. Hesap oluşturmanın bir yolunu seçin: 1 tıkla, telefonla, e-posta ile ve sosyal ağlar veya anlık mesajlaşma programları aracılığıyla. Kişisel verileri girmek için alanları doldurun ve bilgilerin doğruluğunu kontrol ettiğinizden emin olun – hatalar veya kişisel bilgilerin kasıtlı olarak çarpıtılması, doğrulama sırasında zorluklara yol açacaktır. Ardından formun alt kısmında bulunan kayıt ol butonuna tıklayın.

Mostbet’te ilk kez giriş yapıldığında, kayıt sırasında belirtilen bilgileri girmenize gerek yoktur – yetkilendirme otomatik olarak gerçekleşir. Mostbet kayıt, sosyal ağlarda veya anlık mesajlaşma programlarında bir profil kullanılarak yapıldıysa, bu durumda cep telefonu numarasının hemen onaylanması önerilir – aksi takdirde, örneğin bir depozito yenileme ve bonusların etkinleştirilmesi gibi bazı işlemler kullanılamayacaktır. .

Bir hesap oluştururken, bir kumarhanede veya bahisçinin ofisinde çalışan bir bonus seçmeyi unutmayın – kişisel verilerinizi girdiğinizde soldaki ilgili promosyona tıklayın. Kumarhanenin konuklarına ayrıca karşılama etkinliğinden çıkma fırsatı da verilir. Seçilen promosyon, hesabınıza kaydolma ve oturum açma prosedürünü etkilemez.

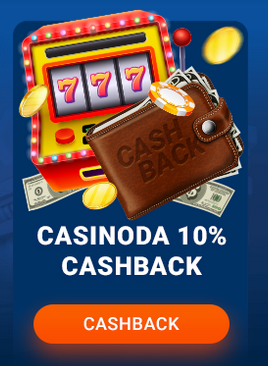

Mostbet kumarhanesi

Site, geniş bir masa oyunları ve slot koleksiyonu içerir. Canlı krupiyeler eşliğinde oynamayı sevenler, girdikten hemen sonra canlı casinoya gitmelidir. Mostbet casino misafirleri şanslarını farklı makinelerle deneyebilir:

- • video yuvaları;

- • ikramiyeler;

- • ruletler;

- • sikbo;

- • blackjack;

- • keno;

- • hızlı oyunlar;

- • bakara ve diğer kumar eğlenceleri.

Mostbet casino, kullanıcıların canlı slot oynayabileceği birkaç çevrimiçi casinodan biridir. Sitede sunulan yazılım koleksiyonu, önde gelen sağlayıcıların yazılımlarından oluşur: Evolution Gaming, Lucky Streak, Amatic, Playson, iSoftBet, Quickspin, Igrosoft, Platipus, vb. Uygun bir arama sistemi, oyunları isme, yöne ve üreticiye göre bulmanızı sağlar.

Siteye üye olup siteye giriş yaptıktan sonra canlı casinoda oynayabileceksiniz. Canlı bölümün koleksiyonu, tanınmış sağlayıcıların yazılımlarından oluşur: Authentic Gaming, Evolution Gaming, Pragmatic Play, Vivo Gaming ve diğer tanınmış şirketler. Mostbet portalının konuklarına, kumar dünyasının en popüler eğlencesinde şanslarını deneme fırsatı verilir: dream catcher, blackjack, barbut, monopoly, rulet, sicbo, poker, jackpotlar, vb. Yeni ürünler ve popüler platformlar sunulmaktadır. ilgili bölümde.

Kumarhane ziyaretçilere çeşitli bonuslar sunar: 100 Euro’ya kadar ilk para yatırmada %100, belirli ödeme sistemleri aracılığıyla hesabı yenilerken %25’e kadar geri ödeme ve ayrıca büyük miktarda para ve değerli hediyeler kazanma şansı. Mostbet, kalıcı olanlara ek olarak, tek seferlik promosyonlar da sunar. Bir promosyon kodunuz varsa, kullanıcı ek avantajlar elde edebilir – bir kombinasyon girmek için hesabınıza giriş yapmalısınız.

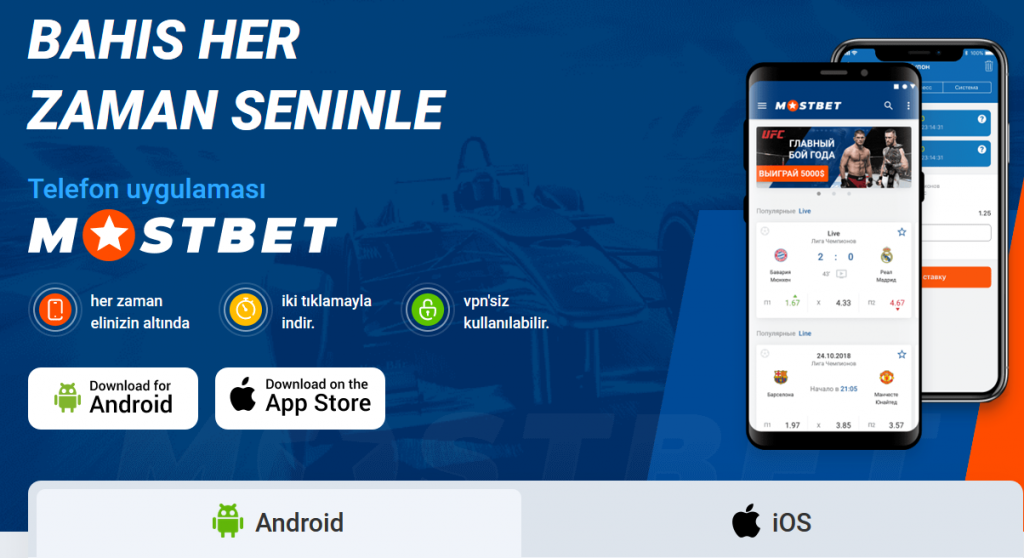

Mostbet app

Oyuncular, en sevdikleri çevrimiçi kumarhane eğlencesi için biraz zaman ayırmaya çalışırken günlük rutinlerini değiştirmek zorunda değiller. Mobil sürüm, uygun herhangi bir yerde oynamanıza izin verir – uygulamayı akıllı telefonunuza veya tabletinize yüklemeniz ve sitenin işlevselliğini uygun herhangi bir yerde kullanmanız yeterlidir. Bir hesap zaten kayıtlıysa, başka bir hesap açmak için zaman kaybetmeden Mostbet‘e giriş yapabilirsiniz.

Kumarhane, uygulamanın Android ve iOS için optimize edilmiş iki sürümünü sunar. Her iki platform da kullanıcılara benzer işlevsellik sağlar. Oyuncular kumarhanelere, canlı kumarhanelere ve bahisçilere erişebilir. Mostbet app kullanıcılar şunları yapabilir:

- depozitoyu yenilemek;

- gerçek parayla ve ücretsiz olarak oynayın;

- bonusları etkinleştirmek;

- turnuvalara katılmak;

- para çekme talepleri oluşturmak;

- müşteri desteğine mesaj göndermek.

Mostbet app portalında bir hesaba giriş yapma yöntemleri, ana sürümde sağlananlara benzer. Android ve iOS uygulamaları kullanıcı dostu bir arayüze sahiptir. Program kodunun iyi optimizasyonu sayesinde trafik tüketimi minimumdur. Uygulamalarda, mostbet uygulaması web sitesinin ziyaretçileri, kumar oyunlarının tam listesine erişebilir.

İndirilebilir platformlar, mobil cihazın işletim sistemi için tamamen güvenlidir. Uygulamalarda, oyuncular sitede düzenlenen etkinliklere ve turnuvalara erişebilir. Ayna aramaya gerek yoktur – uygulamada gerekli tüm hesaplamalar ve eylemler gerçekleştirilir, veriler kullanıcının katılımı olmadan doğrudan kumarhane veritabanına gönderilir.